In the world of heavy machinery, maintenance is paramount. Among the countless maintenance techniques, Line Boring, on-site machining, bore repair, bore welding, slew milling, xy milling, bore welding, bush install, and face welding stand out as highly specialized and essential processes.

Understanding Line Boring and Its Significance

Line Boring refers to the process of machining or enlarging a bore, typically in construction machinery, engines, or turbines. This method ensures that the bore remains perfectly round and aligned, which is crucial for the machinery’s overall performance. The process can be conducted on-site, minimizing downtime and eliminating the need for disassembly and transportation.

On-Site Machining: Convenience and Efficiency

On-site machining plays a pivotal role in modern machinery maintenance. Instead of transporting large components to a workshop, technicians bring the necessary equipment to the site. This approach not only saves time but also reduces logistical complications and costs. Over the years, the demand for on-site machining services has increased, emphasizing the importance of approaches like Line Boring and bore repair.

Read more about Line Boring here.

Bore Repair and Bore Welding: Restoring Integrity

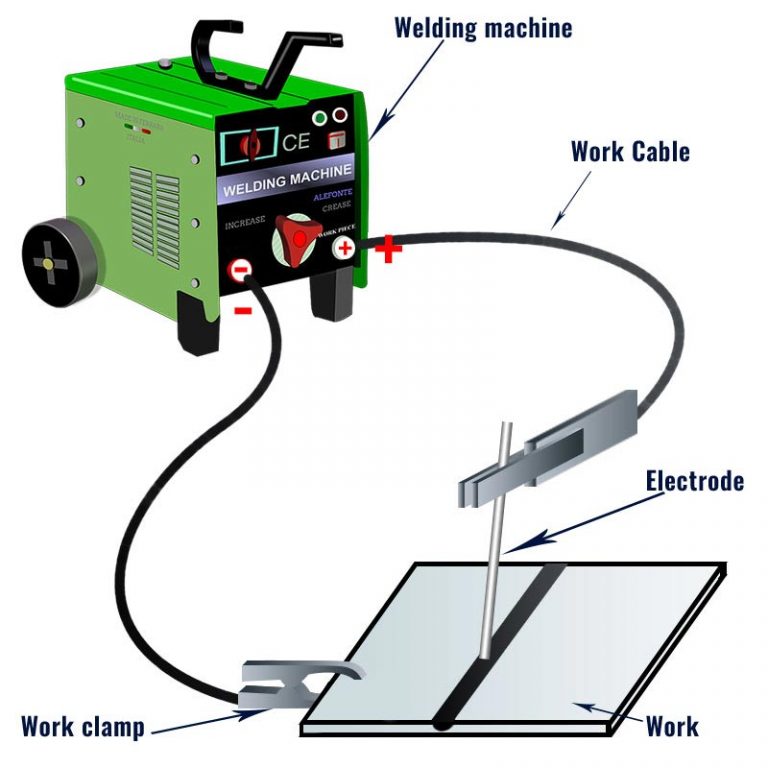

Bores in industrial machinery can suffer from wear and tear, necessitating timely bore repair. The repair often involves machining the bore to remove any imperfections, followed by bore welding to rebuild the original material. Bore welding entails adding layers of metal, carefully matching the original specifications. This step is crucial to ensuring the bore’s longevity and functionality.

Leveraging Slew Milling and XY Milling

Slew milling and xy milling are two important techniques used in conjunction with Line Boring and on-site machining. Slew milling involves the precise rotation of a cutting tool around a stationary workpiece, typically used in large, immovable structures. XY milling, on the other hand, allows for the movement of the workpiece along the X and Y axes, ensuring precise and versatile cutting capabilities. Both methods contribute significantly to achieving the desired tolerances and finishes in machinery components.

The Role of Bush Install and Face Welding in Maintenance

Alongside bore repair and bore welding, processes like bush install and face welding are vital. Bush install involves fitting protective bushings into the bore, which helps reduce wear and improves the overall lifespan of the machinery. Face welding is another critical process, where the end faces of machinery parts are welded to restore or improve their surface finish and structural integrity.

Conclusion

Techniques such as Line Boring, on-site machining, bore repair, bore welding, slew milling, xy milling, bore welding, bush install, and face welding are indispensable in the maintenance of industrial machinery. These advanced processes not only enhance the equipment’s performance but also extend its operational life. Therefore, investing in these specialized maintenance techniques is essential for any industry relying on heavy machinery.