Rather, the welder will feed the filler material right into a puddle. This course of can additionally be very clear, as the alternating present cleans the oxidized layer off the aluminum because it welds. It also prevents aluminum from being contaminated throughout the method.

Read more about welding supplies perth here.

But every step within the welding timeline is an impressive leap in mechanical engineering. If you’d wish to be taught extra about welding, check out our in-depth interview with Jones Welding & Industrial Supply Company. In this article, we’ll take a better look at exactly how welding works. We’ll additionally look at some of the numerous functions for welding, along with the experience and equipment essential to make it all occur. With TIG, the welder pushes the puddle along the seam, ensuring to move back and forth, all the whereas dipping the top of the rod out and in of the puddle with the other hand. Chip off the slag with a welding hammer, after which use a 36-grit grinding wheel to knock the beads down to the encircling metal. To ensure a flat, flush floor, transfer the grinder alongside the weld, not throughout it.

The Results of Welding: What can you expect?

Mixing 75% of Argon with 25% of carbon dioxide will create a mix that provides the best of both gases and reduces the drawbacks. You get shielding that provides good weld area protection, proper shielding, and cleanliness but also good penetration, low spatter, and low prices.

Step-by-Step Guide to Welding Metal Art for Beginners

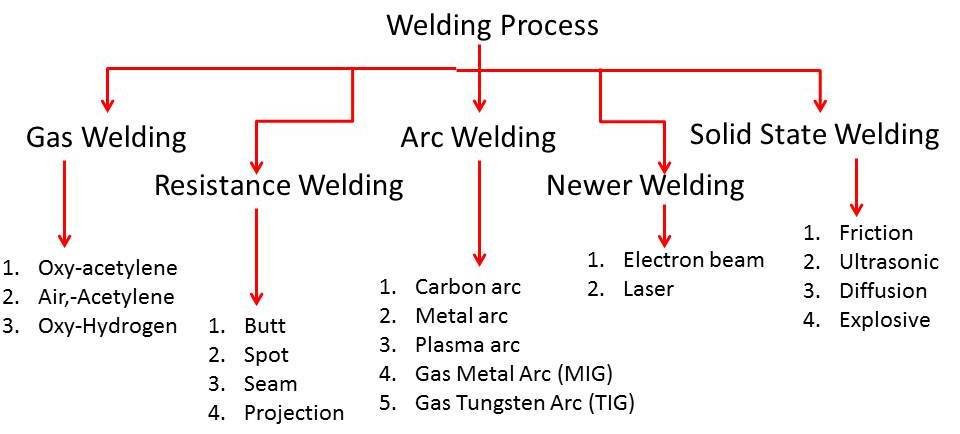

The laser beams utilized in laser welding have a high-powered and centered density, making the vitality pointed in a specific area. This can create a small, deep gap in the materials floor within seconds. The quantity of heat-affected zone could be very small due to the precision of the laser beam. The correct use and maintenance of arc welding power sources not only ensures their normal working efficiency but additionally prolongs their service life. Under normal production situations, single-station arc welding power sources should be used as much as attainable. However, in giant welding workshops similar to shipbuilding workshops, the place there are numerous welding stations and they are concentrated, multi-station arc welding energy sources can be utilized. In addition, there’s also the choice of arc welding inverters.

For example, with DC, magnetic fields can form, induced by the consistent flow of electric present in a single path. In the United States, the American Welding Society (AWS) units today’s welding requirements and presents trade certification.

Read more about speedglas here.