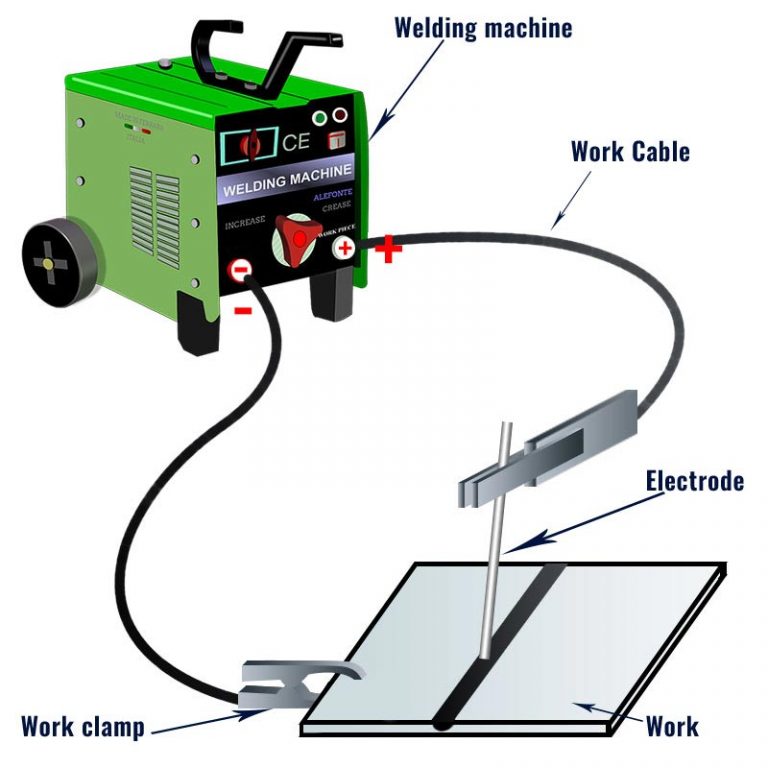

Now that you are conversant in the important elements of the MIG welding system and MIG welding fundamentals, it is time for the center a part of the article – learning the way to MIG weld. Unlike TIG (Tungsten inert gas welding), the complete process, from weld preparation via method and post-weld cleaning, just isn’t so difficult. Therefore, you will not spend too much time from reading this information to laying your first bead. This strategy of welding creates an arc between the bottom material and the gun that heats the fabric until it reaches the melting point.

These are general-purpose MIG wires suitable for a lot of carbon metal welding purposes. However, many welders choose ER70S-6 since it may possibly withstand the warmth of pure CO2 shielding. Performance-wise, these each present glorious results and uniform weld look and may work with low ranges of mill scale or rust. Are you considering starting a career in welding, or just need to weld a few metallic pieces in your storage, but you do not know where to start out from?

Fire Fire Fire Molten metallic can spit a number of ft from a weld. Any sawdust, paper or plastic luggage within the space can smolder and catch fireplace, so hold a tidy area for welding. Your attention will be targeted on welding and it might be hard to see what is going on on round you if something catches fire.

How to Update Software on Your Miller Engine-Driven Welder

This approach is healthier than most for joining dissimilar metals and people which are sometimes exhausting to weld. It even features with sure nonmetals including some ceramics. Laser welding is often used in the automotive, aerospace, and medical industries, in addition to in electronics manufacturing. It is particularly useful for welding materials like aluminum which are tough to weld by conventional strategies. You can weld extremely skinny metals collectively like 2 coke cans or 2 razor blades utilizing TIG. You can successfully weld very thin metals to very thick metals as a result of TIG welding doesn’t heat up a large area of the work piece.

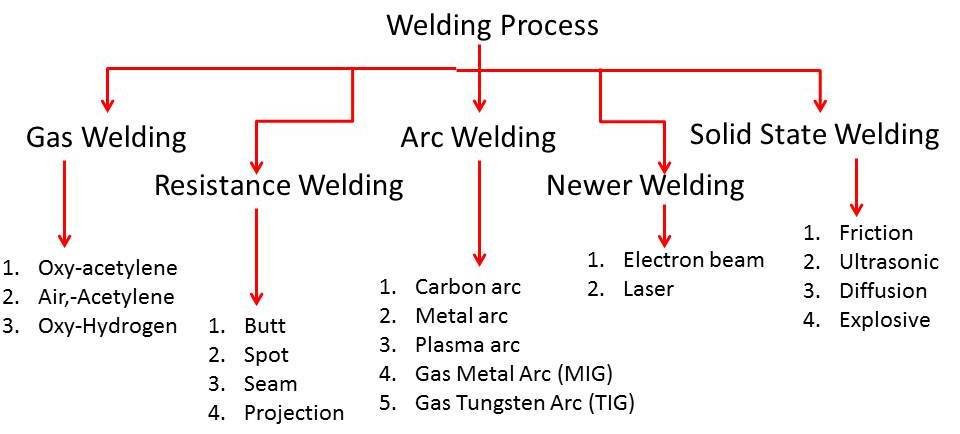

Gas Welding

Read more about welding helmets here.

Electrodes

Since Tungsten has a very high melting point, the electrode doesn’t dissolve beneath intense heat that’s required to create metallic joints. If you take a glance at disadvantages, MIG welding does have some issues. First, you want an external shielding gas for the electrode. MIG welding machines also have a rather high cost and require additional tools to work. For example, you cannot use this technique for overhead or vertical welding.

As you would possibly have guessed, this kind of welding joins two pipes collectively. A lot of the time, the particular techniques used include MIG & TIG welding. Welding manufacturing is when two or extra parts are fused via heat, stress, or both after which type a joint as the parts cool off. Welding is commonly used on metals, however can also be used on issues like wooden. The fabrication process is critical to ensure that supplies are bonded together. Welding is a complex course of that requires balancing many variables to create a structurally sound product.

The vibrations cause the materials to rub in opposition to each other and the friction raises the temperature on the surfaces in touch. This rapid frictional warmth is what sets the circumstances for the materials to bind collectively. Atlas Welding Supply is a leading provider of services that help welding. We are proud to assist a quantity of native welding coaching packages and technical schools.

Read more about welding supplies perth here.